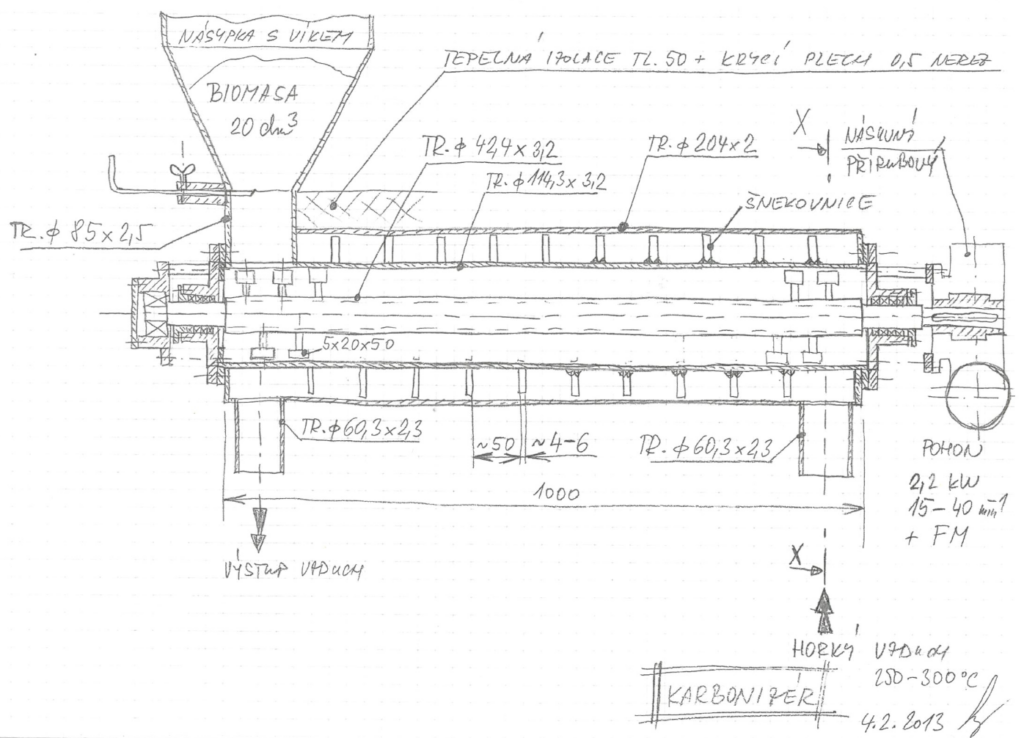

2013 at the beginning there was a hypothesis of biochar production from fermentation residues in a biogas plant.

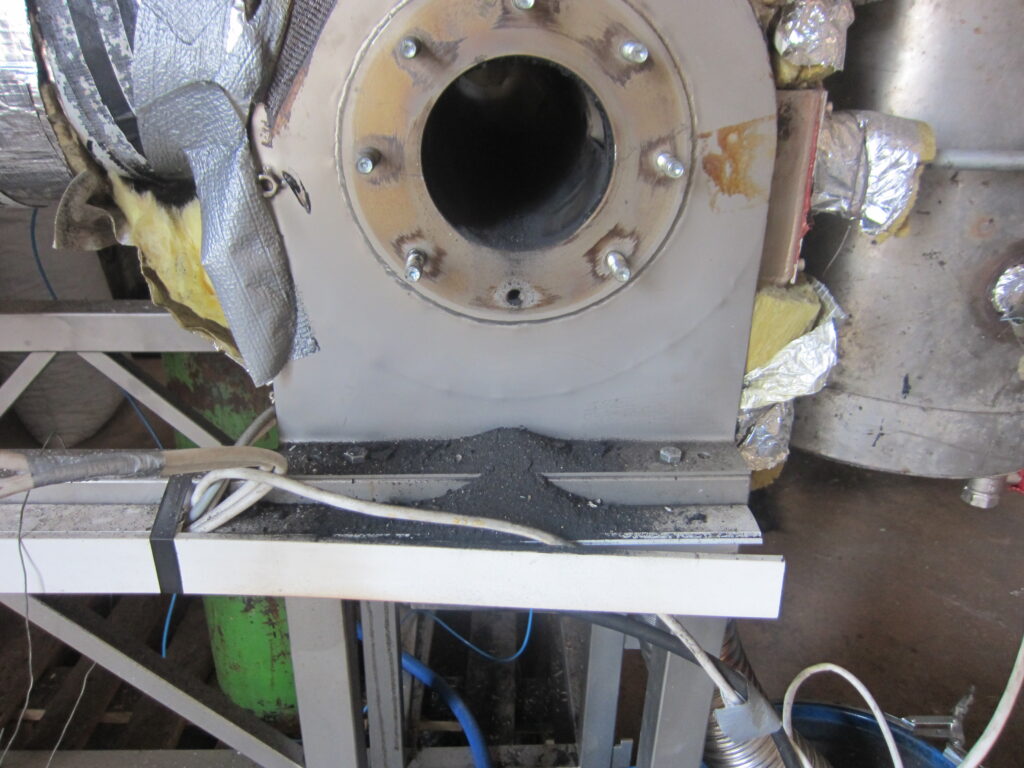

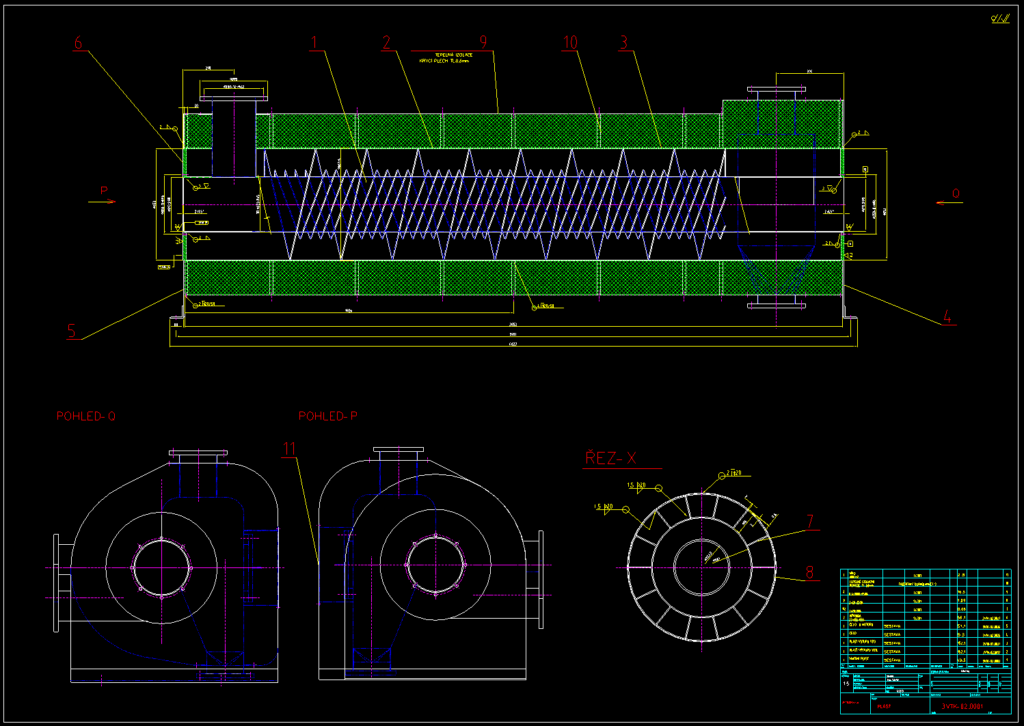

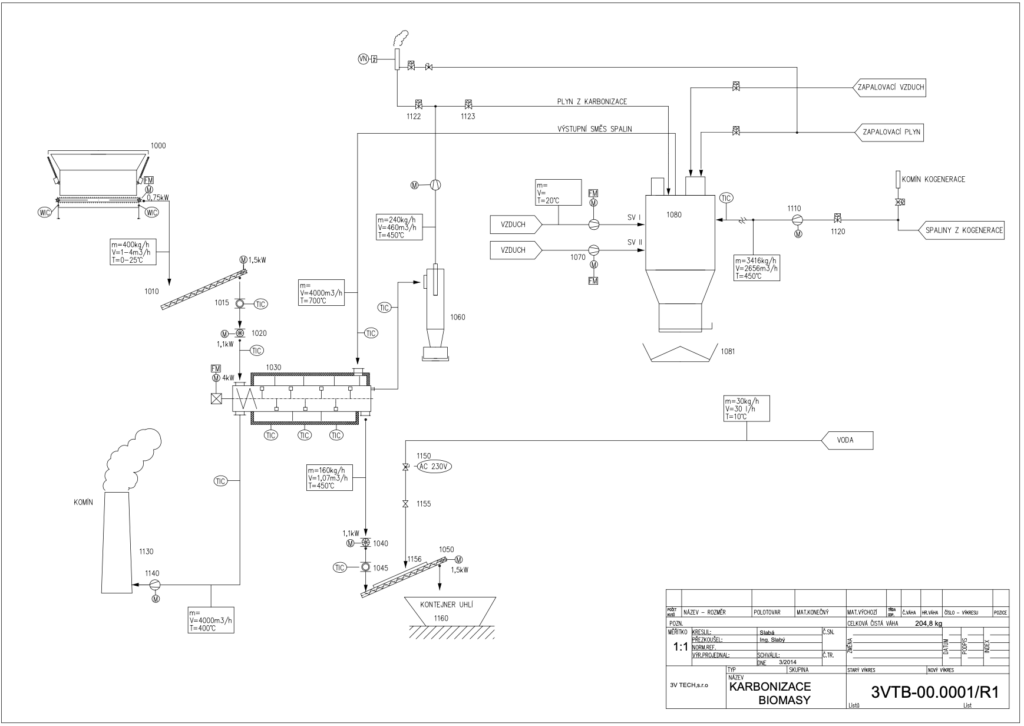

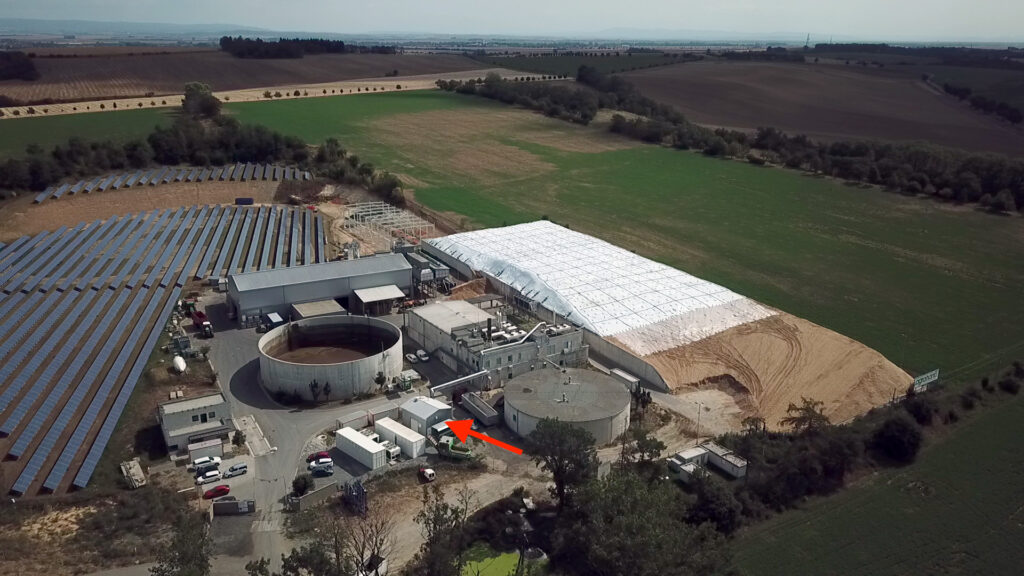

The next step was to take the proven solution to industrial scale. So we designed, manufactured and commissioned the KARBOTECH 500 at the biogas plant in Smržice. The implementation took place in 2014 and the test run in 2016-2018.

| Basic technical data | value |

| production capacity – dry biomass input | 450 kg / h |

| production capacity – biochar produced (by biomass type) | 120 – 140 kg / h |

| operating temperature | 450 – 590 °C |

| operating time | 15 – 50 min. |

| electricity consumption | 18 kWh |

| thermal output of residual heat | 270 – 360 kWh |

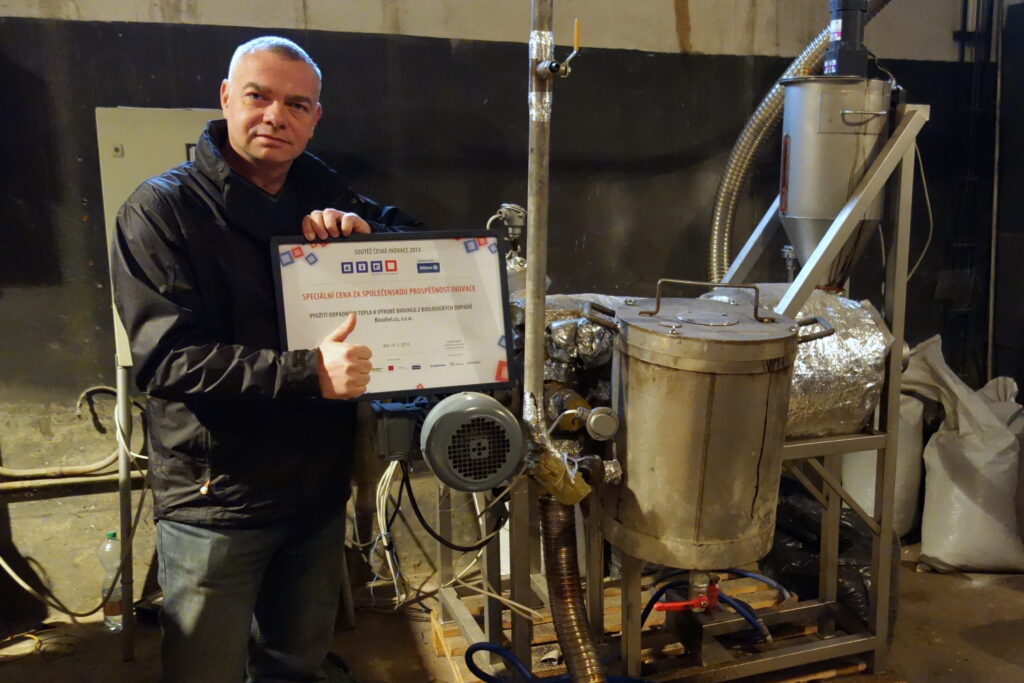

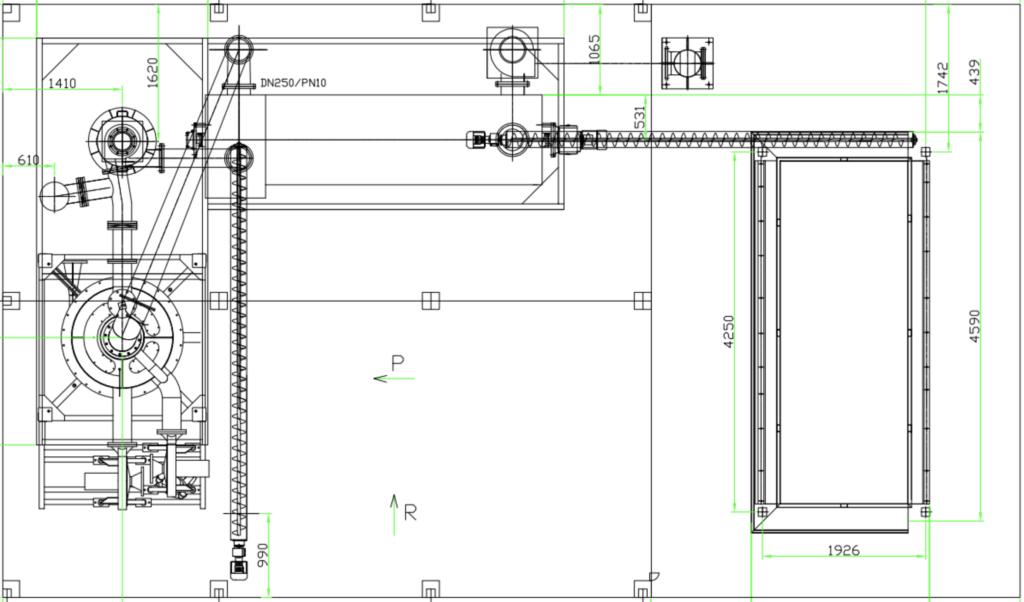

2017 – 2019 This was followed by the scaling up and production of the KARBOTECH 250 with half the capacity.

| Basic technical data | value |

| production capacity – dry biomass input | 250 kg / h |

| production capacity – biochar produced (by biomass type) | 60 – 90 kg / h |

| operating temperature | 450 – 590 °C |

| operating time | 15 – 50 min. |

| electricity consumption | 14 kWh |

| thermal output of residual heat | 120 – 250 kWh |

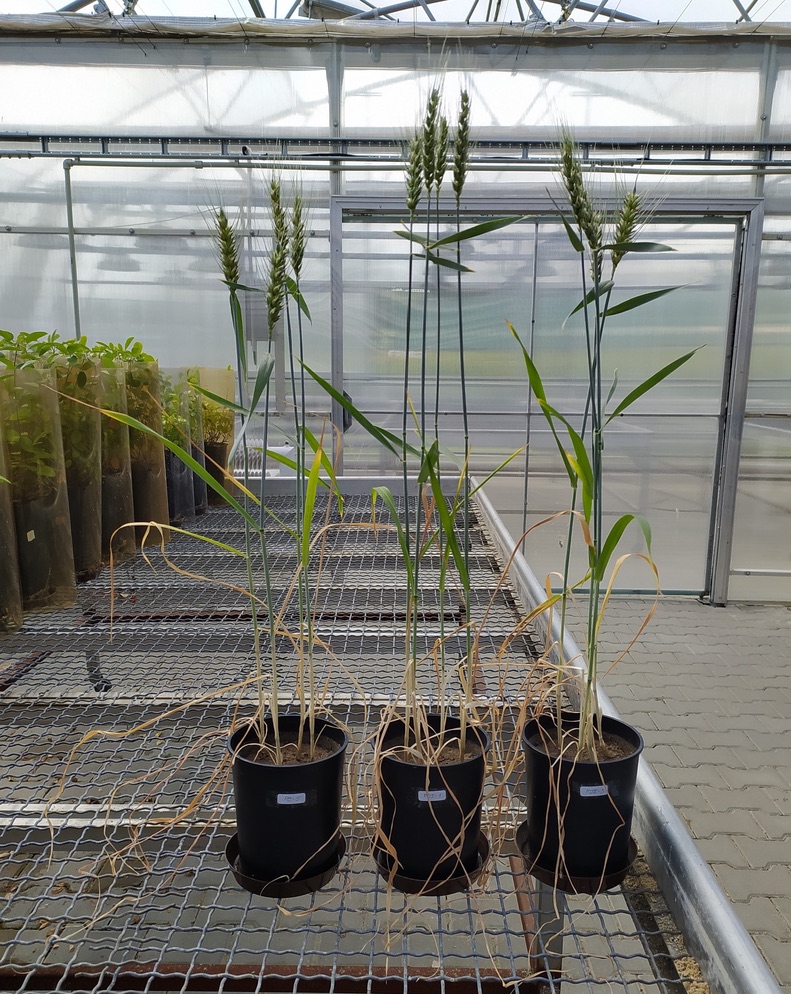

Between 2018 and 2022, the development of the MicroCHAR® soil conditioner took place. From the basic hypothesis of the suitability of biochar as a carrier for rhizobacteria and soil fungi, through the production of the first prototype and the development of the equipment to small-scale „garage“ production and field tests.